55 TPH Columbite Iron Removing Processing Project in Brazil

Project Name:55 TPH Columbite Iron Removing Processing Project in Brazil

Location:Brazil

Mineral:Columbite

Capacity:55 TPH

Main Equipment:SLon WHIMS

Processing Technology:Magnetic separation

Niobium, as one of the rare metals, is widely used in steel, aerospace, superconducting materials, cutting-edge electronics, medical, nuclear industry and other important fields because of its high temperature resistance, corrosion resistance and good superconductivity. It has become an indispensable key strategic metal in modern industry. At present, niobium mainly comes from columbite, pyroclase and other minerals. The world’s available niobium resources are estimated at 4.3 million tons (in metal terms), 95% of which are concentrated in Brazil, with the rest distributed in Canada, Australia, Russia, South Africa, the United States and so on.

Recently, our engineer Harvey Huang has successfully completed the project in Brazil, which has won high praises from the customers. In this project, the Nb2O5 grade of raw ores is about 1.08%, which belongs to high-grade niobium ore. Our Wet High Intensity Magnetic Separator (WHIMS) carry out the task of the two-stage iron removal. First, the raw ores go through the treatment of floating phosphorus and desliming. Its tailings (Nb2O5:1.87%) pass through the WHIMS to reduce the iron content and obtain the non-mags (Nb2O5:2.6%) for further processing. And then, the non-mags travels over niobium floating. The concentrates (Nb2O5:2.6%) enters the second stage of SLon WHIMS for the purification. Finally, the grade of final niobium concentrates can achieve 55.24%.

-

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)SLon has finished the design of the largest SLon-6500 VPHGMS(WHIMS), w…

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)SLon has finished the design of the largest SLon-6500 VPHGMS(WHIMS), w… -

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)…

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)… -

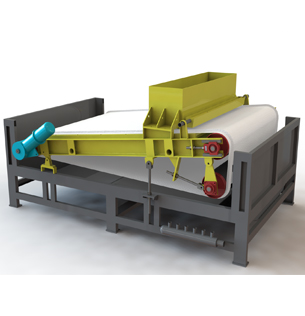

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera…

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera… -

ROTARY SCREENSuitable for screening of coarse particles and grass chips and other i…

ROTARY SCREENSuitable for screening of coarse particles and grass chips and other i…