4,000,000 t/y Iron Ore Concentration Project

Project Name:4,000,000 t/y Iron Ore Concentration Project

Location:Jiangsu, China

Mineral: Iron ore

Capacity:4,000,000 t/y

Main Equipment:SLon WHIMS+LIMS

Processing Technology:Magnetic separation

There is a large iron ore deposit at Meishan Iron Mine in Jiangsu Province of China. In 1970s, a iron ore mining and processing line was built up, producing about 1.3 million tons of iron concentrate a year. The iron concentrate was used as raw material for pellets. However, because of a relatively high content of sulfur and phosphorus (phosphorus is very difficult to remove by metallurgical method), the iron concentrate could not be used alone as a raw material for pellets but as an auxiliary material. Thus, the production of the iron concentrate was limited by the market.

In 1980s, the mine planned to expand its mining and processing scale to 4 million tons a year. The biggest problem was how to reduce the high conclusions of phosphorus and sulphur in the iron concentrate. The mine cooperated with several research institutes and conducted various research work and tests in 1995. One test was the flotation flowsheet and the other was the magnetic flowsheet. Through comparison of hundreds of hours, the magnetic flowsheet showed a number of advantages, namely better processing results, much lower cost, environment friendliness and easier dewatering of the iron concentrate. The mine finally adopted the magnetic flowsheet for innovation and expansion of its production line.

In the course of several years of operation SLon-1500 vertical ring and pulsating high gradient magnetic separators demonstrated their high efficiency and reliability. Up to now, the mine innovated its first processing line and built a second processing line with the magnetic flowsheet. Eighteen SLon-1500 VPHGMS magnetic separators have been installed in the 4 million ton iron ore processing line of the Meishan Iron mine.

-

Iron Ore HGMS for Mineral SelectionThe oxidized iron ore mainly includes hematite, specularite, limonite,…

Iron Ore HGMS for Mineral SelectionThe oxidized iron ore mainly includes hematite, specularite, limonite,… -

Iron Ore HGMS for Tailings UpgradingThe oxidized iron ore mainly includes hematite, specularite, limonite,…

Iron Ore HGMS for Tailings UpgradingThe oxidized iron ore mainly includes hematite, specularite, limonite,… -

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)…

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)… -

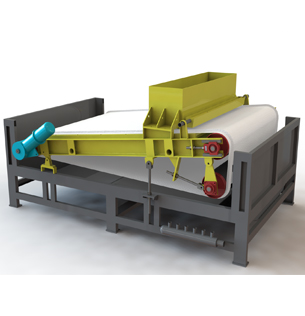

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera…

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera…