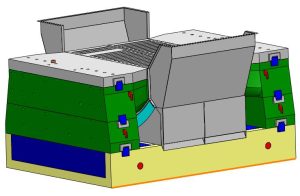

In terms of yoke design, the total weight is 360 tons, which is divided into 13 pieces, and the maximum weight of each piece is only 34 tons. It solves the problems of processing, installation and transportation, and realizes the efficient sealing and transmission of magnetic flux. The measured magnetic field is completely consistent with the theoretical calculation, which has won the national invention patent and patent gold award.

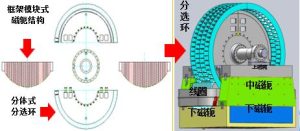

In terms of magnetic matrix design theory, it includes the innovation of high gradient magnetic separator matrix design theory. Computer simulation design realizes the change from number to order, maximum capture and efficient sorting. The magnetic matrix design of SLon-5000 WHIMS includes 640 matrixs and 1.65 million matrix rods. The height of the magnetic matrix box is 1.44 times that of the current mainstream SLon-2500 WHIMS matrix, which satisfies the maximum recovery of fine-grained minerals.

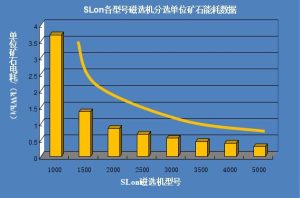

In terms of energy consumption design, the energy consumption per unit ore of SLon-5000 WHIMS is 0.27 kWh/t. The energy consumption per unit ore of SLon-4000 WHIMS is 0.32 kWh/t. And the energy consumption per unit ore of SLon-2500 WHIMS is 0.56 kWh /t. Compared with the SLon-2500 WHIMS, the processing capacity of SLon-5000 WHIMS is increased by 6 times. The energy consumption is saved by 51.7%, and the annual power saving is 2.4 million kWh, which is equivalent to saving 960 tons of standard coal and reducing CO2 emissions by 2350 tons. Compared with SLon-4000 WHIMS, the processing capacity is increased by 2 times. The energy consumption is saved by 15.6% and the annual electricity saving is 410,000 kWh, which is equivalent to saving 164 tons of standard coal and reducing CO2 emissions by 400 tons.

It is also equipped with “the Internet of Things” cloud platform to realize the remote control of magnetic separator, which adapts I/O control method to perform distributed control and monitoring on the remote execution part. It enables the customers to access the control system through the communication protocol to realize remote monitoring and control. There is also remote diagnosis. The system collects on-site fault information through the cloud platform and provides solutions after intelligent analysis.

The Main Technical Parameters of SLon-5000 WHIMS

| Product | SLon-5000 WHIMS |

| Ring Diameter | 5000mm |

| Processing Capacity | 1000 TPH |

| Background Magnetic Field | 0-1.7T |

| Sorting Particle Size | 0-5mm |

| Total Equipment Weight | 520 tons |

| Overall Size | 9900×8000 ×10100mm |

In the future, the development goals of SLon WHIMS are as follows. Firstly, the manufacturing standards are in line with the international level, which realizes the transformation and upgrading of the manufacturing industry. Secondly, it will adapt automation design to realize the self-adaptive adjustment of equipment, automatic control and other functions. Thirdly, the digital integration and visual management will realize remote control, remote diagnosis, and meet the needs of the development of intelligent mines. Fourthly, based on big data and AI algorithm models, the intelligent expert system is established to realize intelligent control and operation and improve the production efficiency of the equipment.