Recently, SLon 20th Anniversary Celebration has been held successfully. This ceremonial event has attracted wide attention in the mining industry and many professionals are invited, which provides a good platform for us to communicate with each other.

In the course of this meeting, it’s noteworthy that the world’s first SLon-5000 WHIMS has made its debut and been delivered. Its design started as early as 2012. To meet the real need of mining development, Dr. XiongDahe initiated the challenge. The core R&D team, a total of 20 people, adjusted design schemes for more than 50 times and made over 2000 drawings. Through multiple experiments, the technical engineers resolved key technical difficulties and kept improving its performance. In 2021, we signed the contract for three sets of SLon-5000 WHIMS applied in ilmenite separation, which achieved the transformation from the drawings into industrial product.

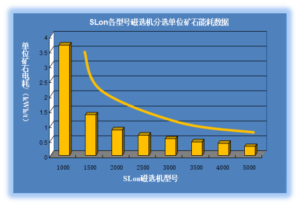

SLon-5000 WHIMS has many advantages compared to other models, especially in processing capacity and energy consumption. Compared to SLon-4000 WHIMS, its processing capacity is twice higher than SLon-4000 (1000 TPH/ 500 TPH). The energy consumption per ton is only 0.27 kWh/t, less than SLon-4000 WHIMS (0.32 kWh/t), which equals to 164 tons of standard coal and 400 tons of carbon emission reduction.

Looking back on the history, SLon has developed into a domestic first-class and internationally renowned leading brand of magnetic separator from the initial small workshop through unswerving efforts. So far, it has served more than 1500 industrial and mining enterprises in more than 30 countries and regions around the world. The market holdings exceed 4000 sets. This time, the world’s first SLon-5000 WHIMS has been officially rolled out and delivered, setting a new record in the application of vertical ring pulsating high gradient magnetic separator. In the future, SLon will still keep the original intention and strive to create a new chapter.